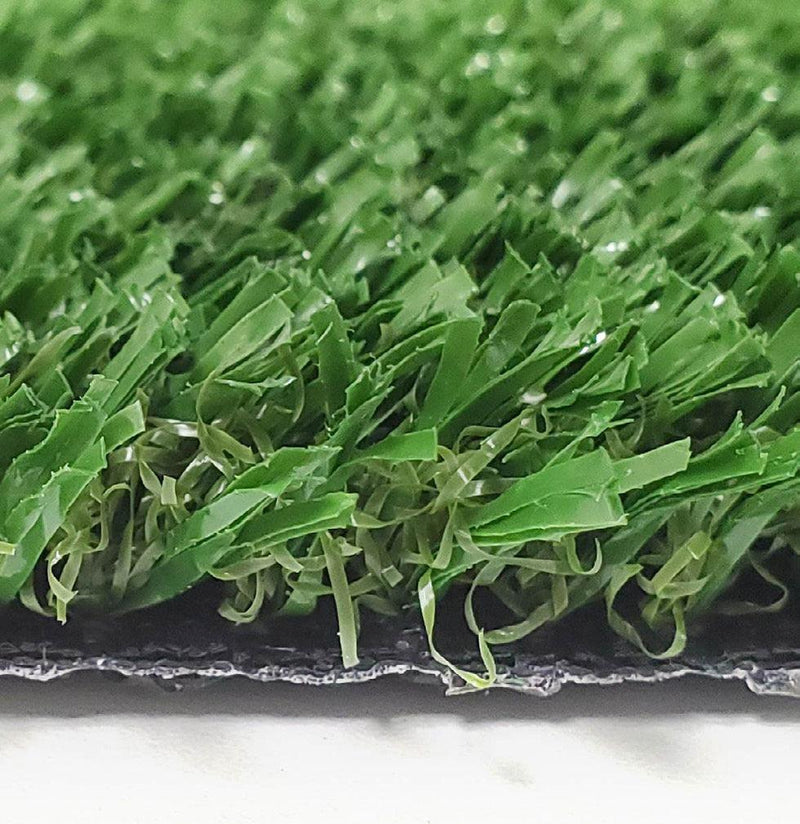

| TURF PROPERTIES | DESCRIPTION |

|---|---|

| Primary/Stalk Yarn Polymer | Polyethylene |

| Secondary/Thatch Yarn Polymer | N/A |

| Yarn Cross Section | Texturized Polypropylene |

| Standard Colors | Pine, Virdian, White, Clay, Florida Blue, Red, Yellow, Orange, Black |

| UV Stabilized | Yes |

| Fabric Construction | Tufted |

| Primary Backing | Dual layered woven polypropylene |

| Coating Type(s) | 5mm Polyurethane Foam/SilverBack™ Polyurethane |

| Perforations | No |

| Yarn Denier/Ends | 4600/8 |

| Texturized Denier/Ends (Thatch) | 4600/8 |

| Recommended Infill | N/A |

| Pile Height | 9/16" |

| Total Weight | 63 oz. |

| Fabric Width | 15 Ft. |

Pure, Quiet Strength.

Imagine having the strength of seven Olympic weight lifters or weighing over 400 lbs and being able to do one armed pull-ups. Our new SilverBack™ is the quiet strength under your new synthetic turf that gives you peace of mind your investment is protected by unmatched strength.

PURE TECHNOLOGY

- SilverBack’s coating system takes advantage of the most advanced technology in the coating industry.

- Engineered with quality in mind from the pure polyurethane chemistry to the application system.

- Features technologically advanced chemistry focusing on offering the highest quality components to create the best coating system available.

- Applied using an application system designed specifically for this coating system in order to have full control of the entire system.

- Certified Quality – OHSAS 18001

Strength is in our DNA.

ArmorLocTM 3L utilizes a complete woven system as the foundation to deliver the world’s strongest artificial turf system. Primary backing plays a vital role in the overall design of an artificial turf system.

ArmorLoc™ 3L is non-directional, dimensionally stable and ensures no excess movement. Combined, ArmorLoc™ 3L with Silverback™ urethane coating and specialized yarns work together binding the DNA of all three components creating a thermoset bond. ArmorLoc™ 3L delivers the science of DNA strand building.

Equipment like playground slides, should be properly grounded per manufactures recommendations. Methods include copper grounding wire and grounding rods.

Features:

- Built into the structure of the product.

- Guarantees total coverage (not topically applied).

- Designed to last the life of the product.

- Electro conductive yarn fiber.

- Grounding proprieties.

Benefits:

- Reduces static discharge.

- No applied coating that requires maintenance.

- Recommended use around playgrounds.

- Antistatic properties.